CFR & CFS FORMED VENT PANELS

The Composite Formed RECTANGULAR (CFR) and Composite Formed SQUARE (CFS) Vent Panels are designed to provide instantaneous overpressure protection for dry, bulk handling and storage equipment, such as dust collectors, air scrubbers, sieves, elevators, driers, silos, spreaders and screens.

The CFR and CFS Vent Panels are designed to allow a full and immediate opening to minimize structural or mechanical damage that may be caused by expanding gases. These gas expansions can result from the deflagration*of dust, gases or mists in equipment, rooms, buildings or other enclosures.

FEATURES

- Operating ratio up to 80% of minimum tagged rating

- Withstands 1-½ psig (0,104 barg) vacuum (consult factory for vacuum requirements exceeding 1-½ psig)

- Non-fragmenting design

- Burst tolerance ±25% for ratings up to 2 psig (0,14 barg) and ±0.5 psig (0,035 barg) for ratings above 2 psig (0,14 barg)

- Excellent cyclic service capabilities (pressures going from positive to negative or negative to positive)

- Full instantaneous opening

- Fully opens under dynamic or static pressure conditions

- INTERCHANGEABLE with existing vent panel applications

- Available with Continental’s B.D.I.® (Burst Disc Indicator) Alarm System.

SPECIFICATIONS

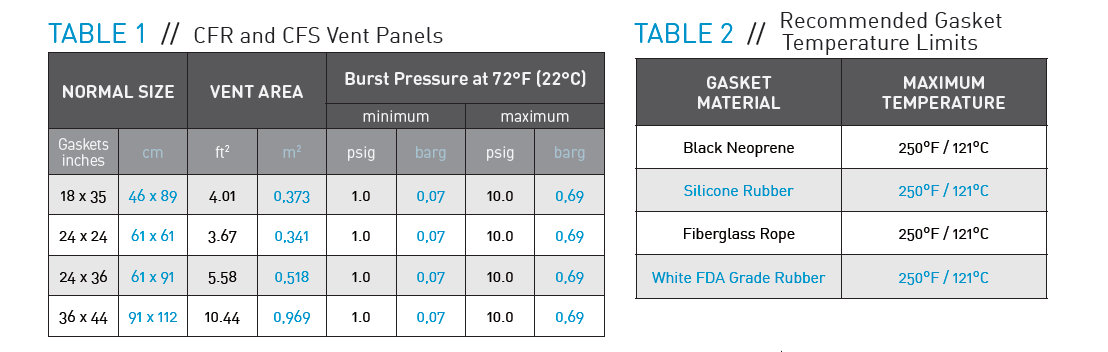

Both the CFR and CFS Vent Panels have a standard material construction of 316 SS top section, TFE TEFLON® seal and 316 SS vacuum support. Each configuration is available in burst pressures from 1.0 psig (0,07 barg) through 10 psig (0.69 barg). Refer to Table 1 for size and pressure specifications.

MAXIMUM OPERATING PRESSURE & BURST TOLERANCE

- The recommended operating pressure for the CFR and CFS Vent Panels is 80%. In addition, CFR and CFS Vent Panels have a burst tolerance of ±25% for burst ratings up to 2 psig (0,14 barg) and ±0.5 psig (0,035 barg) for burst ratings above 2 psig (0,14 barg). To determine the recommended operating pressure, subtract the burst tolerance from the vent panel’s burst rating which establishes the minimum burst pressure, then multiply by 80%.

- For example, a CFR or CFS Vent Panel rated 3.0 psig (0,21 barg) will have a minimum burst pressure of 2.5 psig (0,17 barg) and a recommended operating limit of 1.75 psig (0,12 barg). (Burst rating minus burst toleranceX .80).

Gaskets are available for both vent panel configurations. Materials include black neoprene, silicone rubber, white FDA-grade rubber and fiberglass rope. Gaskets are “key locked” together at the corners to ensure a leak-tight seal (except on fiberglass). Refer to Table 2 for temperature limitations

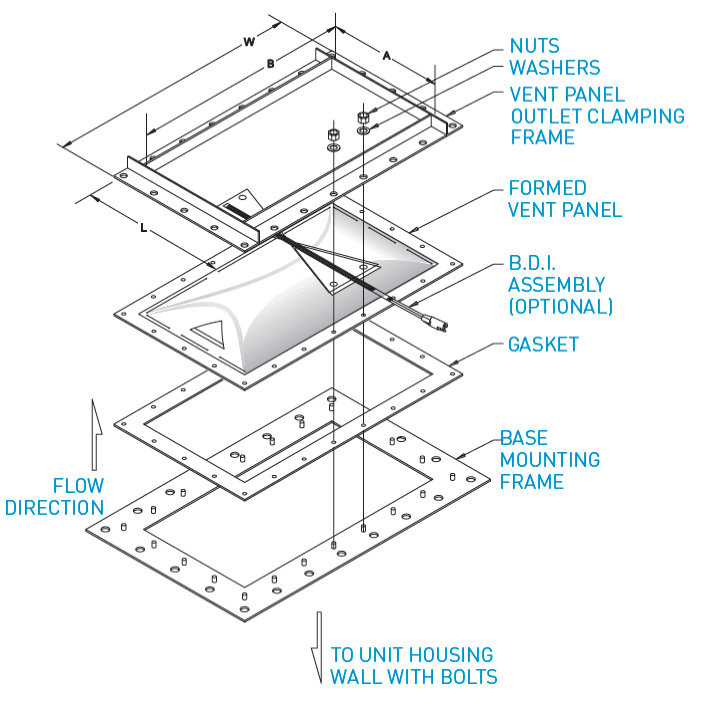

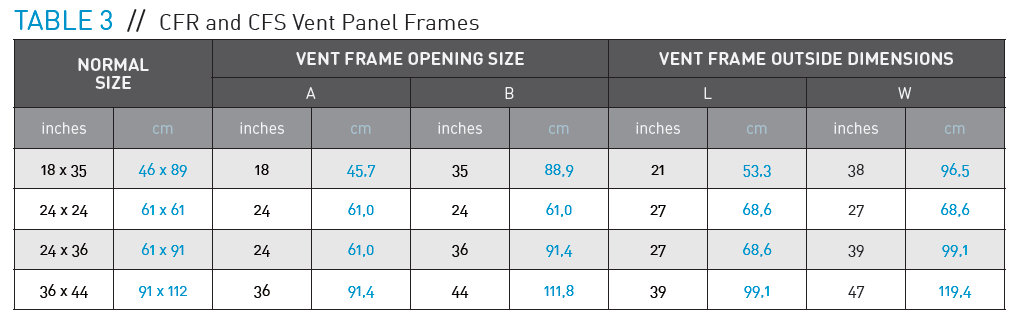

FRAMING

Vent panel framing for square and rectangular configurations are available in carbon steel, stainless steel, aluminum or other specified materials. The outlet frame is typically constructed of 1 ½” x 1 ½” x ¼” carbon steel angle iron, stainless steel angle or aluminum angle. The inlet frame is constructed of flat bar with the vent panel mounting studs permanently attached to the frame. Bolting or welding is used to mount the frame to the structure. Refer to Table 3 for vent panel frame dimensions.