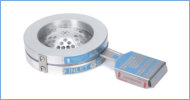

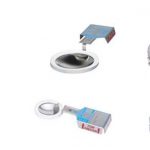

The HPX – Ta Bursting Disc is a Tantalum semicircular scored reverse acting rupture disc designed specifically for use in highly corrosive media, such as bromine, chlorine, HCL, nitric acid or sulphuric acid. In certain concentrations, temperatures and moisture conditions, Tantalum is frequently the only suitable bursting disc material for the application. HPX holder corrosion resistance can be enhanced by Tantalum lining or coating of the holder components.

During the processing of dry chlorine, humidity can enter into the system while pulling a vacuum which increases the mixture of moisture with the chlorine that will corrode other bursting (rupture) disc materials. To prevent an unplanned shutdown for maintenance, the HPX – Ta Bursting Disc is recommended for corrosion resistance where other bursting -rupture disc materials are not suitable.

The HPX – Ta Bursting Disc and HPX-PT (pre-torqued) Holders with Tantalum lining are used in applications where corrosive media is being processed in glass or protective lined vessels. This combination of full Tantalum corrosion protection on the process side of the rupture disc assembly provides the compression required to seal the rupture

disc in the holder, which also provides a high level of corrosion resistance and ensures proper installation of the rupture disc assembly.

The HPX – Ta Bursting Disc with a Tantalum outlet ring which mates with an HPX holder with Tantalum coating on the holder inlet and outlet, provides complete corrosion resistance

Specifications

| Sizes: | 1″ – 12″ (25mm – 300mm) |

| Burst Pressure | 10 – 800 psig (0,689 – 55,2 barg) |

| Manufacturing range | ZERO, -5%, -10% |

| Maximum Recommended OperatingRatio | 90% |

| Available Maximum Temperature Limit | 500° F (260° C) |

| Service | Gas or Liquid |

| NonfragmentingDesign | Yes |

| Withstand Full Vacuum | Yes |

| Operating Conditions | Static,Cyclic or Pulsating |

| Material(s) | Tantalum |

| Seat Configuration | Flat seat |

| Holders | HPX® Insert Holder HPX®-RH (Reduced Height) Insert Holder HPX-PT™ Pre-Torqued Insert Holder, HPX-PT™-RH Pre-Torqued Insert Holder, HPX® Double Disc Insert Holder |

| Compatible with the Following Alarm System | BDI-FLX™ or B.D.I.® |

| Tagging | Three dimensional stainless steel flow direction tag attached to all sizes |

You can contact us by Phone 01726 844707 , Email : info@assentech.co.uk or using the enquiry form below

Some of our customers testimonials

Assentech- pilot operated pressure relief valves service and calibration

Assentech- pilot operated pressure relief valves service and calibration

After conducting a Third Party Witness Inspection, I was most impressed with Ewart and his team, their professionalism, and product knowledge I found to be excellent.

Ian Johnston

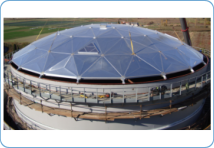

Assentech- Geodesic Dome Installation

Assentech- Geodesic Dome Installation

Assentech were subcontracted to assemble and install a 25m geodesic dome for Shaft G on the Lee Tunnel project. My experience with Assentech from pre-contract through to assembly has been very positive. Unlike other subcontractors I have experienced on this project, Assentech had a very positive attitude to producing the level of documentation required for a project of this scale. Leading to a high quality pre construction packaged approved in a timely manner. The communication regarding the manufacturing process was first class allowing us to easily plan our works and prepare the site. Dome assembly was carried out very efficiently and completed to programme. The task was correctly resourced and well supervised. The work force had a positive attitude and carried out the task safely. In summary from my perspective it has been a very easy subcontract to manage with a high quality finished product.

Robert Colthorpe

Assentech wins supplier excellence award from Eastman Chemicals

Assentech wins supplier excellence award from Eastman Chemicals

We were extremely pleased with the level of service and professionalism demonstrated by Assentech, right from our initial enquiry, through delivery and post installation. As a recipient of only two of these awards made by Eastman Chemical Company in the UK, based on performance in 2014, Assentech are rightly proud of their achievements.

Assentecha-IFR Installations at Vopak, Teesside

Assentecha-IFR Installations at Vopak, Teesside

As you said “you delivered what it said on the tin”. On time and on budget. Your up front engineering to determine the suitability of your product for our application was second to none, i have not seen anyone else in the industry pay as much attention to detail before you get the purchase order number as Assentech.

Garry Lee

Assentech-IFR Installations at Navigator Terminals

Assentech-IFR Installations at Navigator Terminals

Assentech have supported our Navigator Terminal (formerly known as Vopak Teesside) on two important ~

projects by providing technical assistance and supplying and fitting a total of 11 Internal floating roofs. Both projects have been completed on schedule and on budget. Assentech have provided an excellent level of experience and front end engineering support with high quality drawings and documentation. Their specialist on site labour have worked collaboratively with us and Assentech have proven to be open, honest and flexible partners.

We have experience of both their Heavy Duty Pontoon type and Full Contact IFR’s and we continually monitor operation and performance of all lFR units Installed on site and consider the Assentech supplied Matrix brandto be the best in the market with exceptional build quality and rigidity. Our clients have inspected the installations and have always remarked upon the build quality and have been impressed with their strength in fully supporting up to four people without noticeable deformation. The design and construction of their stainless steel shoe seals continue to prove to operate excellently with no noticeable reduction in performance or flotation ability over the time since Installation.

Assentsch have proven to be extremely competitive on price and their installation and inspection activities have always been thorough. Navigator therefore have no hesitation in recommending Assentech to other companies considering their services.

Brian Beddow