” One Stop Solution “

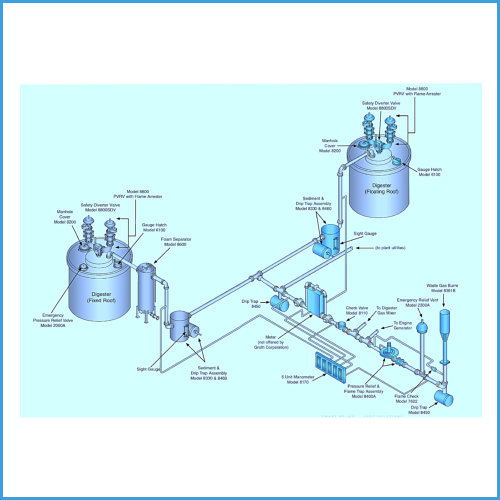

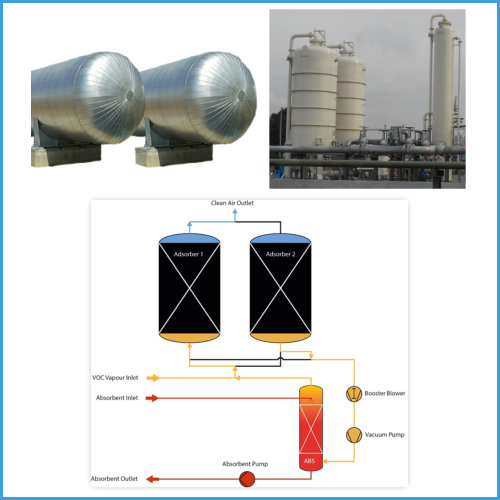

If you are considering purchasing or servicing tank vents (pressure and/or vacuum relief valves “breather valves”), Top or Bottom Loading Systems/Arms, Vapour Recovery Systems/Units, or you are having emission control problems in your storage tank farms; then please get in touch.

Why choose Assentech?

- Legislative Compliance – we are your competent partner in meeting legislative compliance for tank venting and hazardous liquid storage. We give no nonsense and accurate advice that will make your facility safer and more efficient.

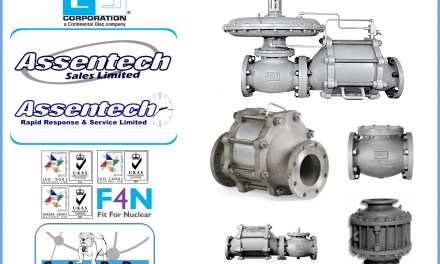

- Wide range of products to meet every need – we offer a comprehensive range of process safety, fluid transfer and tank storage equipment including Breather Valves, Combined Pressure/Vacuum Relief Valves (PVRVs)“, Pressure Relief Valves, Vacuum Relief Valves, Flame Arrestors, Top and Bottom Loading Systems/Arms and Vapour Recovery Systems/Units for loading and unloading terminals.

- Industry Standard 2nd to none- all our tank storage equipment complies fully with API2000 7th Edition including section 6.

- Certification and Calibration – Every Breather Valve, Pressure and/or Vacuum Relief Valve is certified and tested for leakage and calibration on pressure and/or vacuum sides.

- You will know how your product Complies – Full positive material identification and ATEX compliance is standard on all applicable items

- Experience – Assentech has experience in working with the SWA guidelines for tank venting.

- Nationally, & Internationally Recognised – PVRV calibration and maintenance – Assentech Rapid Response & Service Ltd is pleased that our unique approach to servicing tank venting equipment (breather valves, emergency relief valves and any equipment related to tank venting) at customer premises has been recognised by both Valve Suppliers and End Users as follows:

- Skilled Resources – We have an independent team of highly skilled engineers who offer expert advice on legislative adherence/compliance

- 360* Site Review – We offer a complete overview on site operating efficiency with emphasis on Safety, Economic Advantages and Protecting the Environment.

- “Turnkey Solution” – Tank design to API 650 or ISO EN14015, complete with a full set of manufacturing drawings, means that Assentech provides a “turnkey” solution for any on-site construction.

- Free Cloud Based Sizing Software – Assentech offer Free Access to Valve Sizing Software and Tank Venting Calculations: This analysis is concurrent to API2000 and incorporates normal venting, emergency venting, performance flow curve figures for the vents and a tank emission calculation to EPA regulations

In summary, Assentech Sales Limited and Assentech Rapid Response & Service Ltd are here to build strong and safe relationships for all our customers from now into the future. Call our team on 01726 844707 or e-mail us at info@assentech.co.uk and let us demonstrate how we can give you bespoke solutions for peace of mind and the best long term value for money.

Assentech supply, install and service full range of storage tank and fluid transfer equipment in the UK and Europe.

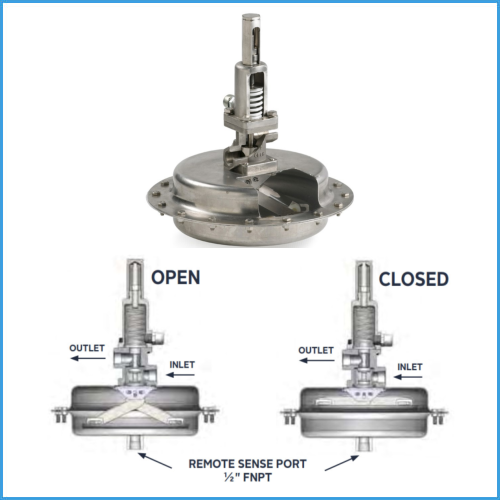

Assentech- pilot operated pressure relief valves service and calibration

Assentech- pilot operated pressure relief valves service and calibration

After conducting a Third Party Witness Inspection, I was most impressed with Ewart and his team, their professionalism, and product knowledge I found to be excellent.

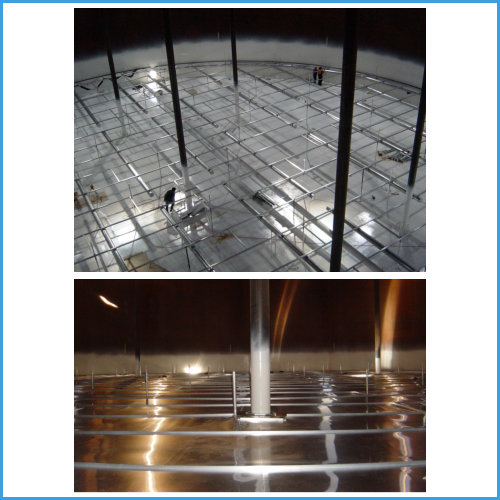

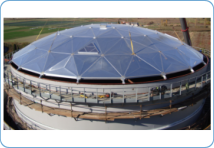

Assentech- Geodesic Dome Installation

Assentech- Geodesic Dome Installation

Assentech wins supplier excellence award from Eastman Chemicals

Assentech wins supplier excellence award from Eastman Chemicals

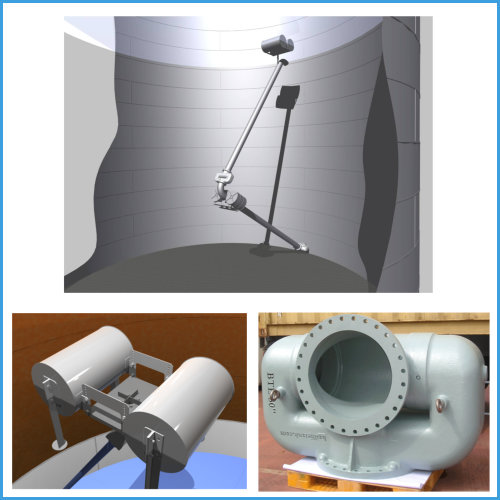

Assentech–IFR Installations at Vopak, Teesside

Assentech–IFR Installations at Vopak, Teesside

As you said “you delivered what it said on the tin”. On time and on budget. Your up front engineering to determine the suitability of your product for our application was second to none, i have not seen anyone else in the industry pay as much attention to detail before you get the purchase order number as Assentech.

Assentech–IFR Installations at Vopak, Teesside

Assentech–IFR Installations at Vopak, Teesside

Assentech have supported our Navigator Terminal (formerly known as Vopak Teesside) on two important ~

projects by providing technical assistance and supplying and fitting a total of 11 Internal floating roofs. Both projects have been completed on schedule and on budget. Assentech have provided an excellent level of experience and front end engineering support with high quality drawings and documentation. Their specialist on site labour have worked collaboratively with us and Assentech have proven to be open, honest and flexible partners.

We have experience of both their Heavy Duty Pontoon type and Full Contact IFR’s and we continually monitor operation and performance of all lFR units Installed on site and consider the Assentech supplied Matrix brand to be the best in the market with exceptional build quality and rigidity. Our clients have inspected the installations and have always remarked upon the build quality and have been impressed with their strength in fully supporting up to four people without noticeable deformation. The design and construction of their stainless steel shoe seals continue to prove to operate excellently with no noticeable reduction in performance or flotation ability over the time since Installation.

Assentsch have proven to be extremely competitive on price and their installation and inspection activities have always been thorough. Navigator therefore have no hesitation in recommending Assentech to other companies considering their services.