Meet the company who is Engineering and Manufacturing some of the highest calibre Bursting Discs on the market

Working with pressurised equipment presents significant risks. Pressure relief devices are major part of protecting both People and Assets.

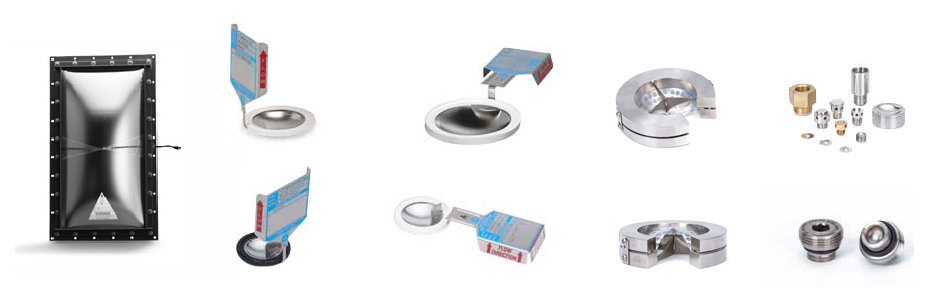

CDC has long been a leader in our industries in terms of both designing and testing Bursting Discs. Their reverse acting HPX discs have been physically proven (not just computer modelled) to withstand over 5 million cycles – and still counting!

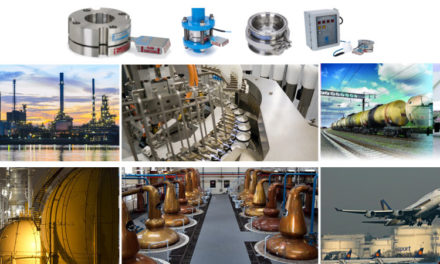

Bursting discs are critical instruments utilised so that companies can ensure process safety as defined by the International Safety Standards (IEC 61508/61511). These devices prove most effective when they fail as closely to pre-established specifications. Continental Disc Corporation specialises in engineering and manufacturing some of the highest calibre Bursting Discs in the world today.

CDC’s Bursting Discs are proven to be essential to Chemical Processing industries seeking to operate systems near designated pressure capacity. The rigorous testing protocol ensure that each disc will perform as stated, giving real peace of mind in critical applications. The variety of materials offered ensures that CDC can provide discs for long-term use in many harsh environments.

Petroleum refining and hydrocarbon industries rely on the sealing capabilities of CDC’s rupture discs for cost-effective system protection with a focus on fugitive emissions; and protecting equipment.

Beverage, food, dairy and pharmaceutical industries depend on CDC’s Sanitary line of discs, specifically developed to meet stringent purity requirements. This family of discs offer a range of solutions including holders that ensure no dead space in the process (particularly important in the food industry). They also offer a choice of gaskets such as peroxide or platinum cured silicon to suit every application.

HPX Bursting Discs are the most advanced bursting discs on the market designed for the high demand applications. Intertek awarded CDC’s HPX, BDI, and BDI-FLX products the coveted SIL rating of four (4), a score that cannot be improved upon.

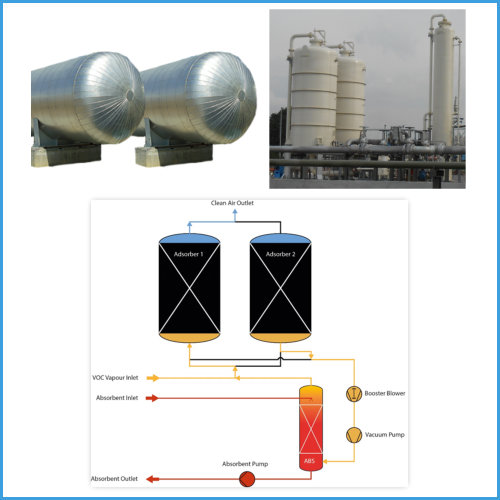

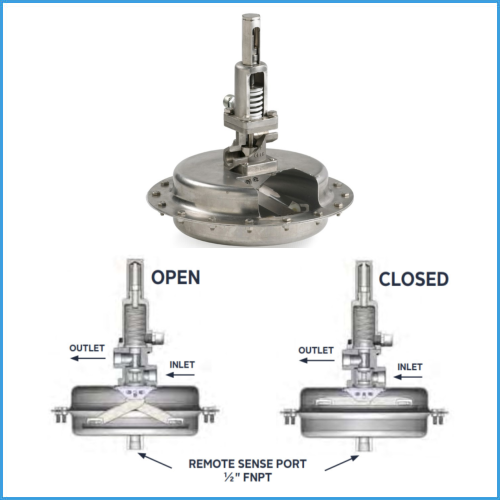

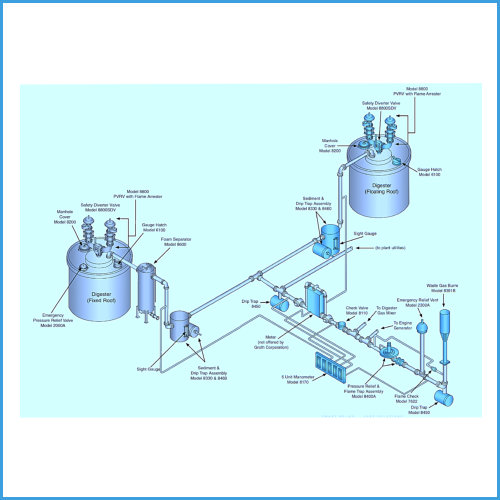

CAL-VAC and POS-A-SET Bursting Discs are highly accurate, double acting pressure relief devices designed to protect processing and storage tanks against implosion or overpressure conditions that can occur in Positive Pressure “overfill, external fire, steam regulator failure…” or in Vacuum Relief “liquid pump out, flash vacuum due to CIP cool rinse, primary vent malfunctions, blanket gas or air regulator failure.

ICON & ICON-TL Bursting Discs are specifically designed to protect transportation vessels such as railroad portable containers, tank cars, over-the-road tank trucks and other vessels that transport liquid or gas products, from potentially damaging over pressure conditions.

The B.D.I. (Burst Disc Indicator) Alarm System is designed for use with Continental Disc bursting discs. The B.D.I. Alarm System signals the system operator when a rupture disc has burst to relieve an overpressure or vacuum condition.

Continental Disc Corporation bursting discs have a full line of accessories available for rupture disc products. Accessories are available to enhance the bursting disc assembly’s ability to work under different environments. This may include helping with installation, monitoring operation, or aiding the corrosion resistance of a holder.

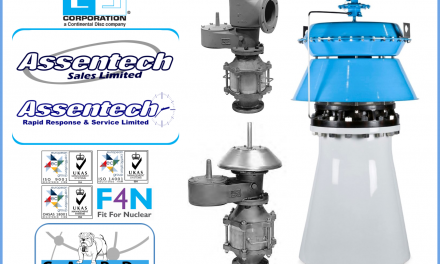

Assentech Sales Limited is a leading supplier of equipment, services and technical expertise in the fields of Tank Storage, Fluid Transfer and Process Safety.